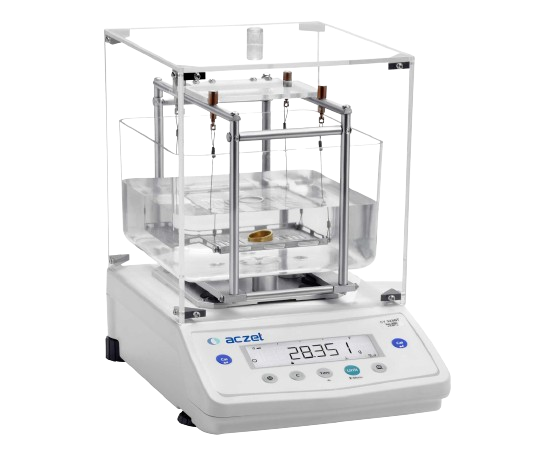

Calibration Weight

- Calibration test weighing is a critical procedure for ensuring the accuracy and reliability of precision weighing equipment.

-

Key Points:

Purpose: Calibration test weighing verifies that the weighing instrument provides accurate measurements by comparing its readings against known standard weights.

Frequency: Regular calibration is essential, depending on usage frequency, environmental conditions, and manufacturer recommendations. This ensures the balance remains accurate over time.

Procedure: The process involves placing test weights on the scale, recording the readings, and comparing them to the known values. Any deviations are noted and corrected as needed.

Environmental Condition: Calibration should be conducted under stable environmental conditions, including temperature, humidity, and absence of vibrations, as these factors can affect accuracy.

Adjustment: If discrepancies are found during calibration, adjustments may be made to the weighing machine to correct any inaccuracies.

Certification: Calibration often requires certification by a qualified technician or service provider, especially in regulated industries, to ensure compliance with industry standards and regulations.

Impact on Accuracy: Regular calibration ensures that the weighing machine provides accurate results, which is crucial for quality control, inventory management, and regulatory compliance.